Haomei aluminum

This is the post excerpt.

This is the post excerpt.

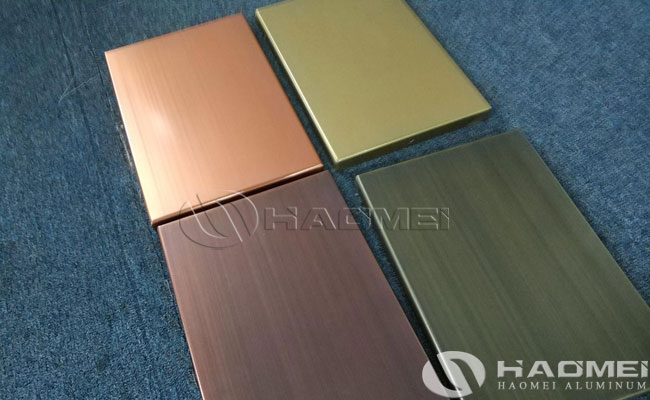

6061 anodized aluminum sheet is 6061 aluminum sheet alloy through anodizing process with an oxidized surface. 6061 anodized aluminum can be processed in thicknesses of 0.2 – 500 mm, with the widest range of 950 – 1800 mm, commonly used tempers are T6 and T651. it can ensure that the thickness of the oxide film is uniform and up to standard.

6061 anodized aluminum sheet is an sheet alloy composed of aluminum, magnesium and silicon, with excellent mechanical properties and processing performance, is widely used in aviation, automotive, construction, electronics and other industries. This aluminum alloy significantly improves the mechanical properties and corrosion resistance of aluminum by adding alloying elements such as magnesium and silicon, as well as small amounts of copper and zinc.

Aluminum 6061 plate has medium strength and good workability, and can be easily cut, bent, drilled and welded. It also has excellent corrosion and oxidation resistance and can be used in harsh environments for long periods of time without damage. In the construction industry, 6061 aluminum sheet is commonly used for decoration and protection of exterior walls, roofs, doors and windows, etc. Its surface can be sprayed, anodized and other treatments to increase its beauty and corrosion resistance.

When 6061 aluminum plate after anodizing treatment, its surface will form a dense layer of aluminum oxide film, further improving its corrosion resistance and hardness. This oxidation treatment can make the surface of the 6061 aluminum plate more beautiful and increase its service life.

In summary, 6061 anodized aluminum sheet with oxidation treatment, not only retains the original excellent performance, but also enhances its surface corrosion resistance and aesthetics, so that it is more advantageous in a variety of applications.

This resource is from https://www.aluminum-coil.net/6061-anodized-aluminum-sheet.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

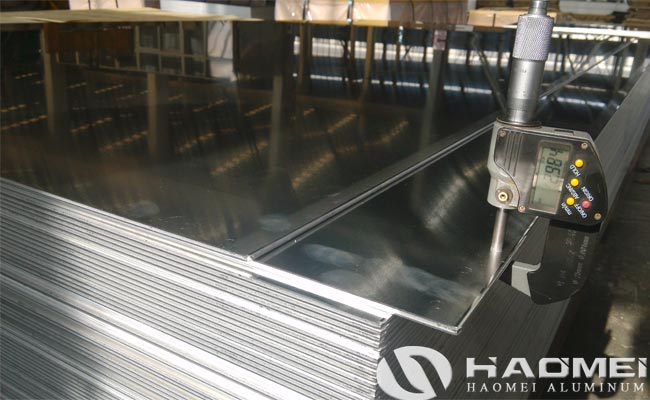

Thick aluminium sheet supplier mainly produce aluminum sheet 1060, 2024, 3003, 5052, 5083, 6061, 6082, 7075 with thickness over 8mm. In the industry, aluminum sheets are usually classified according to their thickness. Thin aluminum sheets are usually less than 1mm thick, plain aluminum sheets are between 1mm and 8mm thick, and thick aluminum sheets are more than 8mm thick. This classification is mainly based on the processing method, for example, aluminum sheets up to 8mm can be processed by choosing cold-rolling equipment, while aluminum sheets more than 8mm have to be manufactured by using hot-rolling equipment. Thick aluminum sheet is widely used in many industries such as construction, furniture, automotive, aviation, electronics and so on.

The production process of thick aluminium sheet supplier mainly includes the following steps:

Smelting:

Aluminum ingots after melting into liquid aluminum, at this time you can add some alloying elements to further improve the mechanical properties of aluminum sheet.

Casting:

Molten aluminum liquid through a special casting process, casting aluminum slab billet.

Rolling:

Aluminum slabs are rough rolled in a heated state, and the thickness of the aluminum slab is initially pressed. After rough rolling, the aluminum slab needs to be heated continuously and rough rolled again until it reaches the ideal size and thickness. Afterwards, finish rolling is carried out, and after the fine rolling process, the aluminum sheet becomes the aluminum sheet and coil material of specific specifications and dimensions.

Annealing:

Annealing is an indispensable step in the production of aluminum sheets, which gives them good mechanical and physical properties. The annealing process eliminates the internal stresses of the sheet by applying controlled heating and cooling treatments to the aluminum sheet, thereby increasing the bending capacity and plasticity of the sheet, and improving its workability and corrosion resistance.

As for the use of thick aluminum sheet, it is widely used in many fields:

Processing materials for various pressure vessels: such as storage tanks, oil drums, reactors, etc. These vessels require high strength and stiffness.

Aviation field: used as materials for processing thin-walled parts such as airplane fuel tanks and fuel pipes, which have complex shapes and harsh working conditions.

Shipbuilding: used as hulls, keels and superstructures, etc. The shipbuilding industry requires high strength and corrosion resistance of the materials used.

Chemical equipment: used to make a variety of structural parts of the substrate, chemical equipment, the working conditions are harsh and the medium has chemical toxicity or corrosive.

In general, thick aluminium sheet supplier process aluminum sheet with high quality and it plays an important role in industrial production due to its excellent performance and wide range of applications. The specific choice of alloy and thickness of aluminum sheet needs to be based on the actual application scenarios and needs.

This resource is from https://www.aluminumsheet.net/thick-aluminium-sheet-supplier

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

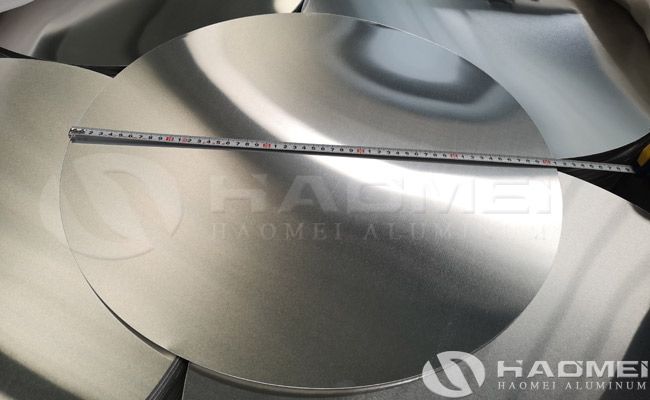

12” aluminum circle is an aluminum disc product with diameter of 12 inch, equals to 30 cm or 300 mm. Aluminum circle of 12 inch diameter are used for a variety of purposes due to their material properties and size advantages. As the diameter of 12 aluminum circle is about 30 cm, the thickness range is 0.40mm-6.00mm. 12” aluminum circle generally choose from 1000 series, 3000 series and 5000 series to be produced and processed, the key to hot rolled, anodic oxidation treatment without color difference, the common situation is O, H12, H14, aluminum alloy composition and strength of the situation can be customized. Common raw materials: 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052 and other series of products, the most common used grades are 1060 and 3003 soft aluminum circle.

The 12” aluminum circle is common seen aluminum discs size, the specific uses include but are not limited to:

Kitchenware manufacturing:

12 inch aluminum circle is often used to manufacture cookware such as pots and pans, baking pans, etc. due to its good thermal conductivity. It can quickly and evenly conduct heat to the ingredients and improve cooking efficiency.

Sign making:

12 inch aluminium circle can be used as the base material for signage, and various kinds of signage, such as road signs and billboards, can be made by engraving and spraying.

Outdoor antenna making:

Aluminum circle 12 inch can be processed into desired antenna shape and structure through cutting, bending, welding and other processes. Its lightweight characteristics make installation and maintenance easier, while its corrosion resistance ensures the long-term stability of the antenna in the outdoor environment.

Making the lampshade:

Aluminum, as a metal material, has good electrical and thermal conductivity, which helps to ensure the safe use of the lamps and lanterns. Aluminum also has excellent corrosion resistance and is resistant to moisture and oxidation, making it particularly suitable for outdoor lampshades or lampshades that have to withstand certain environmental challenges.

The 12” aluminum circle produced by Haomei Aluminum has exquisite appearance, production and processing of thoroughly automated technology, continuous, high level of automation technology, to prevent the old machinery and equipment production and processing of scratches and oil stains caused by the production and processing of high-efficiency production, an hour can produce 2-3 tons / production line. Aluminum circle 12” is produced from hot rolled aluminum coil, the original material tensile strength, internal structure and organizational structure, grain size is better than cold rolled goods, at the same time, at this stage of high-end lighting fixtures, kitchen utensils production and processing will be carried out after the molding of the surface treatment, that is, anodic oxidation treatment, sustained stamping of aluminum not only high tensile strength, and anodic oxidation treatment of the actual effect of the stronger, especially suitable for the application of this type of goods.

This resource is from https://www.aluminumdiscs.com/12-inch-aluminum-circle.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

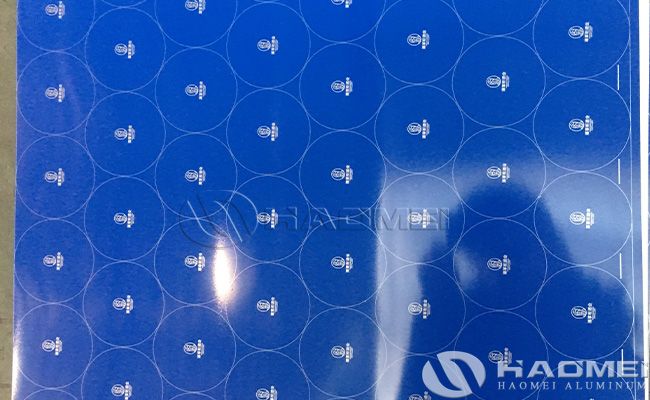

Aluminium divider strip are often used to make floor dividers due to their unique physical properties, different sizes can be offered by Haomei Aluminum. The thickness of aluminium floor divider strips can be selected according to specific needs. Generally speaking, aluminum strips with thicknesses between 0.3mm and 3.0mm are more common, and these thicknesses are both strong enough and easy to process and install. Aluminum floor dividers usually require a certain width to ensure their stability and visual effect. Common aluminium dividing strip widths range from 20mm to 100mm, depending on the design of the divider and the environment in which it will be used. It is important to note that in addition to the specifications of the aluminum strip, factors such as its material and surface treatment should also be considered. Some aluminum divider strips may undergo special treatments, such as painting and oxidation, to enhance their aesthetics and corrosion resistance.

Aluminium divider strip is a decorative material that is commonly used for home improvement and building exterior decoration. Aluminum divider strips are a very popular spacer product and are widely used because they are lightweight, easy to install and aesthetically pleasing. Aluminum floor divider is usually made of oxidized aluminum strip, which gives it a very beautiful texture. The hardness and corrosion resistance of the treated aluminium divider surface is also greatly enhanced. The following are the advantages and applications of aluminum strips in the production of floor dividers:

Lightweight and strong:

Aluminum strips are lightweight, which makes the floor dividers easier to install and reduces the construction burden. At the same time, the high strength of aluminum ensures that the strips are not easily deformed or damaged during long-term use.

Good ductility and plasticity:

Aluminum strips can be made into various shapes and sizes of floor dividers through different processing techniques, such as cutting, bending, welding, etc., to meet the needs of different floor coverings.

Corrosion and oxidation resistance:

Aluminum has good corrosion and oxidation resistance, which makes the floor dividers maintain their original performance and appearance in wet environment and prolong their service life.

Aesthetically pleasing:

The surface of aluminum strips can be treated in a variety of ways, such as spraying and oxidizing, giving them different colors and textures that can be coordinated with the flooring material and enhance the overall decorative effect.

Environmental protection and energy saving:

Aluminum is a recyclable metal, the use of aluminum strip to make floor dividers helps to reduce resource consumption and environmental pollution, in line with the development trend of green building.

In summary, aluminium divider strip is widely used in the production of floor dividers because of its lightweight, strong, corrosion-resistant, beautiful and other advantages. Choosing aluminum strip as the material of floor divider can effectively improve the quality and effect of floor covering.

This resource is from http://www.aluminum-strip.com/news/aluminium-divider-strip.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

The aluminum slugs for aerosol can making usually come in a variety of sizes to accommodate different aerosol can sizes and shapes. In terms of specifications, the thickness, size and other parameters of the aluminum slugs for making aerosol cans can be customized according to the design requirements of the aerosol can. Thickness is a key factor in the strength and tightness of an aerosol can and is usually determined by the purpose of the aerosol can and the pressure it needs to withstand. Size, on the other hand, is based on the shape and size of the aerosol can to choose the right aluminum slugs.

1070 aluminum slug is the main product of aluminium slug for making aerosol can. As for the properties of 1070 aluminum slugs for aerosol cans, they are mainly reflected in the following aspects:

Excellent corrosion resistance:

1070 aluminum slug, as a high-purity aluminum, has good corrosion resistance, which can resist the erosion of aerosol cans by the external environment and ensure the long-term stability and safety of the product.

Good processing performance:

1070 aluminum slug has good plasticity and can be processed into various shapes and sizes of aerosol cans through stamping, stretching and other processes. Meanwhile, its surface finish is high, which is conducive to subsequent surface treatment and decoration.

Lightweight:

Aluminum itself has a low density, making the aerosol cans produced lighter in weight, which is easy to carry and transport, and also reduces the cost.

Environmental protection:

Aluminum is a recyclable metal material, the use of 1070 aluminum slug to make aerosol cans meets the requirements of environmental protection, helps to reduce environmental pollution and waste of resources.

Safety performance:

Aluminium aerosol cans made of 1070 aluminum slugs have good sealing performance, which can effectively prevent the leakage of the substance inside the can and ensure the safety of the product.

Aluminum aerosol cans are formed by a single piece of aluminum slug through one-time punching or cold extrusion molding, the amount of material to save, high production efficiency, the amount of product waste is small, and the production of the body of the can has no side seams, usually dome cover and the body of the can as a whole, the shoulder of the can cans can be formed into a smooth curve, high compressive strength, good air resistance (not because of the existence of interfaces and leakage caused by the case), moisture-proof performance is good, the shading performance is strong, and it is easy to printing, exquisite appearance.

This resource is from https://www.aluminumslugs.com/2024/04/25/aluminum-slugs-for-aerosol-can-making/

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

Chromized and dos treated aluminium sheet acquires a range of superior properties and characteristics that make the treated stock more suitable for bottle cap production and applications.

Chromized and dos treated aluminium sheet offer a number of unique advantages.

First of all, chroming treatment can form a uniform and dense chromium oxide layer on the surface of the aluminium sheet. This chromium oxide layer not only effectively prevents the erosion of the aluminum sheet by rain, chemicals and other environmental factors, but also improves the corrosion resistance of the aluminum sheet in corrosive media such as liquor and beverages, which greatly extends the service life of the aluminum sheet. At the same time, because the formation of chromium oxide film is carried out through physical and chemical oxidation reaction, its coverage of the surface of the aluminum sheet uniformity is good, without special mechanical and chemical treatment. In addition, the chroming treatment significantly improves the hardness and abrasion resistance of the aluminum sheet for bottle caps, enhances its impact resistance, and further enhances the performance of the aluminum sheet. In addition, the chromated film improves the abrasion resistance of the cap stock, reducing wear and tear during transportation, storage and use.

Secondly, with DOS treatment of aluminium sheet for bottle caps is aluminum substrate through pre-treatment cleaning, chemical layer and then coated with a layer of DOS oil, (DOS oil is the abbreviation of dioctyl sebacate), DOS treatment of the main role is to prevent oxidation and scratches, DOS oil treatment of the substrate is coated with DOS oil on both sides, the general amount of DOS treatment for the 10-80mg% 2Fm2, which can isolate the aluminum sheet from the air, thus preventing it from rusting and further improving the rustproof ability of the aluminum sheet. At the same time, DOS oil treatment also helps to improve the abrasion resistance and corrosion resistance of the aluminum sheet, so that it can still maintain good performance in complex environments. After DOS oil treatment of the substrate for the next process manufacturers and then slit into sheets and strips and then coated and printed into different specifications to facilitate the subsequent processing of the pre-coated aluminium sheet substrate for the use of the caps factory, DOS oil pre-coated aluminum coil due to the more flexible subsequent processing, the use of a considerable amount.

Combining the effects of chroming treatment and DOS oil treatment, this aluminium sheet for bottle caps not only has excellent corrosion resistance, but also good wear resistance and hardness, which can meet the needs of bottle caps and other components used in complex environments. In addition, this treatment also helps to improve the surface quality of the aluminum sheet, making it more beautiful and durable.

Overall, the chromized and dos treated aluminium sheet has excellent performance performance, which is ideal for making bottle caps and other parts.

This resource is from https://www.aluminium-for-closure-caps.com/a/chromized-and-dos-treated-aluminium-sheet.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

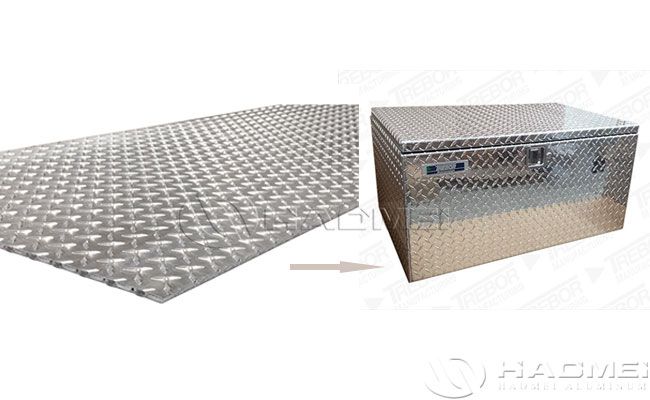

In aluminum toolbox manufacturing, the use of toolboxes aluminium checker plate can not only improve the overall strength of the toolbox, but also add a unique visual effect to its appearance. Nowadays, many large trucks are using aluminium checker plate to make toolboxes, which are mainly used for storing and carrying all kinds of tools, such as pliers, screwdrivers, hammers and so on. At the same time, due to its lightweight and high strength, aluminum too box is also suitable for field operations and rescue sites.

The selection of material for making tool box and the thickness of tool box are decided by the customer’s demand. The material of aluminum alloy tool box has three kinds of aluminum alloy 3003, aluminum alloy 5052 and aluminum alloy 5083, and the thickness of toolboxes aluminium checker plate can be chosen from 1.5mm, 1.85mm, 2.35mm, 2.5mm and so on. In addition to the basic size specifications, you also need to consider the surface treatment and quality of aluminum checker plate. A quality aluminium checker plate should have uniform oxide film thickness, good gloss and hardness, and good corrosion resistance. These factors will directly affect the appearance and service life of the toolbox. The aluminium toolboxes made from aluminum chequer plate are beautiful in appearance, light in quality, strong in load bearing, more innovative in design, and very strong and durable, which also provides better protection during transportation and use. The lightweight aluminum tool box can be mounted on pickup trucks, trailers, pump trucks, motorcycles, etc. It is used to store a variety of tools such as loading and unloading tools planks, jacks, wrenches, pry bars, and even vacation camping supplies.

Van aluminum tool box using toolboxes aluminium checker plate has the following advantages:

1, lightweight:

The density of aluminum checker plate is low, compared with other metal materials are lighter, so you can reduce the weight of the toolbox, easy to carry and use.

2, high strength:

The high strength of aluminum chequer plate, can withstand greater pressure and impact, to ensure that the toolbox is strong and stable.

3, beautiful and generous:

Unique pattern design makes the aluminium checker plate looks more beautiful and generous, but also increases the added value of the toolboxes product.

4, corrosion resistance:

Aluminum checkered plate has good corrosion resistance, not easy to rust, can maintain the beauty and value of the tool box for a long time.

This resource is from https://www.aluminum-tread-plate.com/a/toolboxes-aluminium-checker-plate.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

Marine grade aluminium flat bar is an aluminum parallelogram bar cut from marine grade aluminium, which is widely used in shipbuilding due to its advantages of lightweight, corrosion resistance, easy processing, etc. The aluminum grades of marine grade aluminum flat bar are 5000 series and 6000 series, including 5052, 5083, 5086, 6061 and so on. 5083 marine grade aluminum alloy is an aluminum-magnesium alloy, typical rustproof aluminum grade, whose corrosion resistance, processability, strength, etc. are in line with the requirements of marine aluminum processing, and is therefore widely used in the superstructures and upper devices, such as masts, chimneys, gun mounts of gunships, lifting devices and so on. This kind of marine grade aluminium bar has a series of excellent performance characteristics, which makes it occupy an important position in shipbuilding.

Materials and specifications of marine grade aluminium flat bar:

The material of marine grade aluminum flat bar is usually 5000 series aluminum alloy, indicating and magnesium element aluminum. According to different application scenarios and requirements, different materials of marine aluminium flat bars have corresponding specifications.

1. Dimensions

The thickness of marine grade aluminum flat bar is generally 0.2 – 8.0mm, the width is generally 20 – 600mm, and the length is generally 1000 – 6000mm, of which the more common specifications are 1.0 × 20 × 2000mm, 1.0 × 30 × 2000mm, 1.0 × 40 × 2000mm, 1.0 × 50 × 2000mm, and so on.

2. Surface treatment

Marine grade flat aluminum bars generally need surface treatment, common anodic oxidation, electrophoretic coating, electrostatic spraying and other treatments. These treatments can improve the surface performance of flat aluminum bar, improve its corrosion resistance and corrosion resistance, so that it has better stability and durability in different environments.

5083 marine grade aluminium flat bar is an important material commonly used in shipbuilding. This kind of flat aluminum bar is mainly made of 5083 aluminum alloy, which belongs to the aluminum-magnesium alloy and has a series of excellent performance characteristics, especially suitable for shipbuilding field.

First, 5083 aluminum alloy has excellent corrosion resistance, especially in seawater environment. This enables 5083 marine grade aluminum flat bars to effectively resist the erosion of seawater, ensuring the durability of ship components and reducing maintenance frequency and costs.

Secondly, 5083 marine grade aluminum bar has good workability and formability. It can be shaped by cutting, stamping, cold bending and other processing methods to meet the needs of various complex shapes and structures in shipbuilding. At the same time, its excellent welding performance also facilitates the connection with other components to improve the stability and safety of the overall structure.

In addition, the flat aluminum bar is also characterized by high strength and light weight. The high strength makes it able to withstand the various forces that a ship may encounter during navigation, while the lightweight feature helps reduce the weight of the hull and improve the ship’s navigation speed and fuel efficiency.

In shipbuilding, marine grade aluminium flat bar is commonly used in the manufacture of hull structures, decks, masts and other components. Its excellent performance characteristics make the ship more robust and durable, and also help to improve the safety and sailing efficiency of the ship. Overall, marine grade flat aluminum bar is an indispensable and important material in shipbuilding, and its excellent performance and wide range of applications make it occupy an important position in ship manufacturing.

This resource is from https://www.marine-grade-aluminum-plate-sheet.com/a/marine-grade-aluminium-flat-bar.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

Aluminium 6063 t5 alloy is a medium-strength, heat-treatable, reinforced alloy that belongs to the 6000 series of aluminum alloys. The following are detailed introduction about its alloy composition, specifications, physical properties, chemical properties and applications:

1. Alloy composition

6063 t5 aluminum alloy is mainly composed of aluminum, magnesium, silicon and other elements, of which aluminum is a residual, the content of other elements are strictly controlled within a certain range to ensure that the alloy’s excellent performance. Specifically, the content of copper (Cu) does not exceed 0.10%, the content of manganese (Mn) does not exceed 0.10%, the content of silicon (Si) is between 0.20 and 0.60%, the content of magnesium (Mg) is between 0.45 and 0.90%, the content of iron (Fe) is not more than 0.35%, the content of titanium (Ti) is not more than 0.10%, the content of zinc (Zn) is not more than 0.10%, the other element content (individual) not more than 0.05%, other elements content (total) not more than 0.15%.

2. The specifications

Aluminium alloy 6063 T5 generally are processed in to aluminum sheet plate and aluminum profile. To the specification of 6063 aluminum sheet, thickness 8 ~ 100 mm is commonly used, the length and width are generally 1250 * 2400 mm, 1500 * 3000mm. Alu 6083 t5 it can be made into a variety of shapes and specifications of the aluminum profile, such as angle aluminum, channel aluminum, aluminum bar, round tube, square tube, etc., to meet the needs of different areas.

3. Physical properties

The density of 6063 T5 aluminium alloy is about 2.7g/cm³, the coefficient of linear expansion is 23.5×10^(-6)/℃, and the thermal conductivity is 201~218W/(m-K). These physical properties make 6063 T5 aluminum alloy excellent in thermal conductivity, electrical conductivity and processing performance.

4. Chemical Properties

The chemical properties of aluminium 6063 T5 alloy are mainly reflected in its corrosion and oxidation resistance. As the alloy added magnesium and silicon and other elements, so that the alloy has excellent corrosion resistance, can resist a variety of chemical erosion. At the same time, the alloy also has good oxidation resistance, can be in the high temperature environment to maintain stable performance.

5. Applications

Aluminum 6063 T5 alloy has a wide range of applications, including transportation, energy, urban construction, pipe, military, aviation, lighting and other fields. In the industrial field, 6063 T5 aluminum alloy is often used to make shelves, brackets, industrial automation equipment, factory and office benches, belt conveyor lines, solar panel supports, aluminum access ladders, anti-static benches, etc. because of its good workability and expandability. In addition, 6063 T5 aluminium alloy is also widely used in the framework of architectural aluminum doors, windows and curtain walls to ensure that the doors, windows and curtain walls have high wind pressure resistance, assembly performance, corrosion resistance and decorative properties.

To sum up, aluminium 6063 t5 alloy is a kind of material with excellent performance, which has a wide range of application prospects in various fields.

This resource is from https://www.aluminumhm.com/media/news/aluminium-6063-t5.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com

This is the introduction of HAOMEI aluminium 2024 t3 data sheet including alloy composition, specification, physical properties, chemical properties and application area.

Alloy composition of 2024 T3 aluminum alloy:

2024 T3 aluminum alloy is an aluminum-copper-magnesium duralumin-type alloy with the following approximate mass fractions: Si 0.5, Fe 0.5, Cu 4, Mn 0.9, Mg 1.5, Zn 0.25, Ti 0.15, and the rest is aluminum content. In addition, it may contain some other elements and impurities.

Specification of aluminium 2024 t3:

2024 T3 aluminum alloy is commonly available in the form of tubes, plates, rods, aluminum rows, aluminum wires, etc. The specifications can be customized according to the actual application requirements. Haomei Aluminum mainly offer 2024 t3 aluminum sheet, 2024 t3 aluminum plate, 2024 t3 aluminum tubes, 2024 t3 aluminum bars and other related products that used for aircraft industry.

Physical Properties of aluminum 2024 t3:

2024 t3 aluminum alloy has high strength, plasticity, fatigue life, fracture toughness and resistance to fatigue crack extension. Its hardness, tensile strength and yield strength are significantly improved in heat-treated states (e.g. T3/T351 state). For example, its ultimate tensile strength can reach 58,000-62,000 psi (400-427 MPa), yield strength is 39,000-40,000 psi (269-276 MPa), and elongation is 10-15%.

Chemical Properties of 2024 t3 aluminium:

The corrosion resistance of 2024 T3 aluminum alloy is general, in order to improve its corrosion resistance, anodic oxidation treatment and painting methods or surface cladding aluminum layer are often used.

Applications of 2024 t3 aluminum:

Due to the excellent comprehensive performance and high-temperature creep resistance of 2024 T3 aluminum alloy, it is often used in places where high strength but low weight ratio is required, such as the skins and engine compartments of commercial and military aircrafts that are often subjected to high temperatures of 121~150°C, as well as other aircraft structural parts with high strength requirements. Also, its good cutting and machining properties have led to a wide range of applications in the manufacturing industry.

Please note that specific aluminium 2024 t3 data sheet including alloy compositions, specifications and properties may vary depending on the manufacturer and the specific product, so it is recommended to check the relevant product information or consult a professional according to the actual needs.

This resource is from https://www.aircraft-aluminium.com/a/aluminium-2024-t3-data-sheet.html

Should you be interested in, please contact us at:

Haomei Aluminum

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@aluminumhm.com